- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

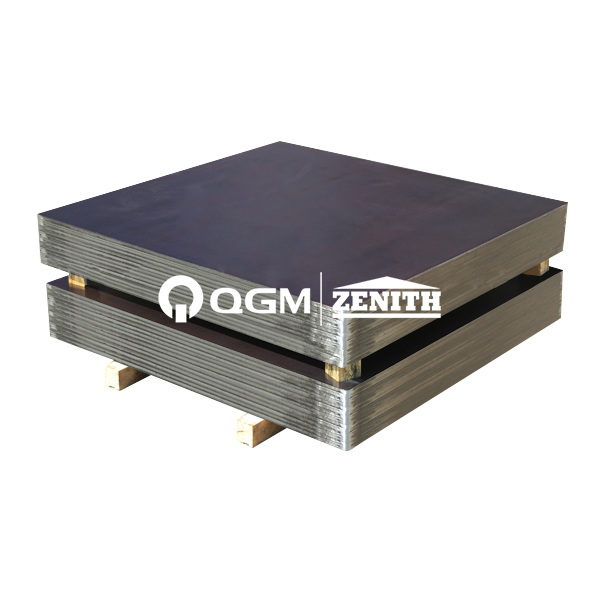

Quick-Change Block Machine Pallet: Revolutionizing Production Efficiency in Manufacturing

2025-04-10

The quick-change block machine pallet has emerged as a game-changer in the manufacturing industry, significantly enhancing production efficiency and flexibility. This innovative tool is designed to quickly and easily switch between different types of blocks, reducing downtime and increasing productivity. As manufacturers seek to streamline their operations and meet diverse customer demands, the quick-change block machine pallet has become an essential piece of equipment.

In recent years, the demand for quick-change block machine pallets has surged, driven by the increasing complexity of manufacturing processes and the need for flexibility. These pallets are particularly valuable in industries such as automotive, electronics, and construction, where production lines must be rapidly adapted to handle various components and parts.

The quick-change block machine pallet consists of a modular design that allows for easy switching between different block configurations. This is achieved through a combination of standardized components and interlocking mechanisms, ensuring quick and precise changes. The pallets are typically made from durable materials such as steel or aluminum, which provide both strength and flexibility.

Manufacturers in the quick-change block machine pallet industry are focusing on continuous innovation to meet the evolving needs of the market. Key trends include the development of more compact and lightweight designs, enhanced ergonomic features, and improved integration with automated systems. These advancements not only improve the efficiency of the production process but also enhance operator comfort and safety.

The market for quick-change block machine pallets is segmented into various applications, including automotive assembly, electronics manufacturing, and construction equipment. Each segment requires specific features and configurations to meet unique production needs. For instance, automotive manufacturers may require pallets that can quickly switch between engine blocks and body panels, while electronics manufacturers may need pallets designed for handling small, delicate components.

One of the critical benefits of quick-change block machine pallets is the significant reduction in production downtime. Traditional block changeovers can take hours, but with these pallets, the process is streamlined, often completed in minutes. This rapid switching capability allows manufacturers to respond more quickly to changing production demands and customer orders.

Moreover, the quick-change block machine pallets are designed to be highly adaptable, making them suitable for a wide range of applications. They can be easily customized to meet specific requirements, whether it's for handling different sizes and shapes of blocks or for integration with existing production lines. This adaptability is particularly important in industries where product lines are frequently updated.

The global market for quick-change block machine pallets is expected to grow in the coming years, driven by factors such as increasing manufacturing efficiency, the need for flexibility in production lines, and the adoption of automated systems. However, the industry also faces challenges such as competition from alternative solutions, the need for continuous innovation, and the requirement to meet stringent quality and safety standards.

In conclusion, the quick-change block machine pallet is revolutionizing production efficiency in the manufacturing industry. By providing rapid and flexible switching capabilities, these pallets are enabling manufacturers to meet diverse production needs and customer demands more effectively. As the industry continues to evolve, manufacturers are focusing on innovation to enhance the performance and adaptability of these pallets, ensuring they remain at the forefront of production technology.