- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

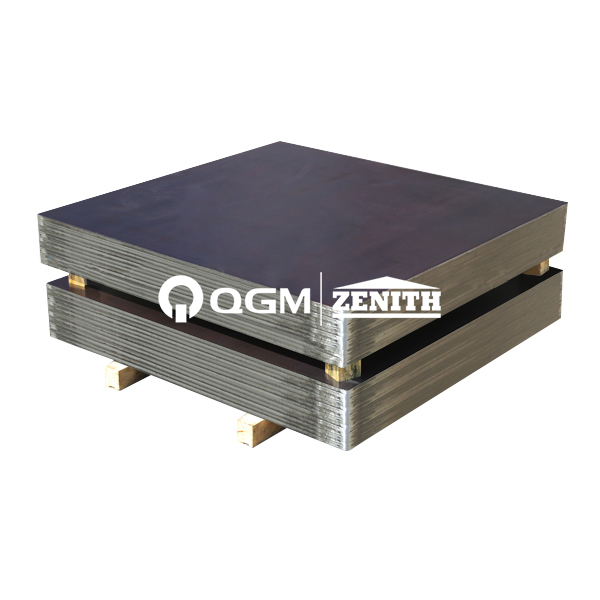

What is the maintenance of Block Machines Pallet?

2025-03-19

Routine cleaning and inspection of block machine pallets are vital to prevent issues such as concrete buildup, warping, and damage. Here are some tips for maintaining block machine pallets effectively:

1. Regular Cleaning:

Regularly cleaning block machine pallets helps to remove any concrete residue that may accumulate during the production process. Use a pressure washer or a hose to rinse off debris and dirt from the pallet surface. This simple step can prevent material buildup and ensure that blocks are produced to the highest standards.

2. Inspection for Wear and Damage:

Periodically inspecting block machine pallets for signs of wear and damage is crucial for identifying potential issues early on. Look for cracks, splinters, or warping that may affect the quality of the concrete blocks. Replace any damaged pallets promptly to avoid production delays and maintain efficiency.

3. Proper Storage:

Store block machine pallets in a dry and flat area to prevent them from warping or bending. Avoid stacking pallets unevenly, as this can lead to structural damage over time. Proper storage practices can help prolong the lifespan of block machine pallets and ensure consistent block production.

4. Utilize Protective Coatings:

Consider applying a protective coating or sealant to block machine pallets to enhance their durability and resistance to moisture and wear. This extra layer of protection can prolong the lifespan of the pallets and reduce the frequency of maintenance tasks.